Welding: The Backbone of Steel Structures

- gokul raj

- Dec 17, 2024

- 2 min read

Welding isn’t just about joining metal; it’s about creating strong, seamless structures that stand the test of time. Whether in the shop or on-site, welding is a critical part of the steel fabrication process. And for many builders, the combination of shop welds and site bolts is the perfect mix of efficiency and cost savings.

At Sharcon, we understand that welding isn’t just a process—it’s a foundation of your project’s success. Let’s talk about how we approach it to make your life easier as a builder or fabricator.

Why Weld Strength Matters

The strength of a weld is essential to the integrity of your structure. Here’s what it depends on:

Base Metal: The material you’re working with.

Filler Metal: What fills the gaps matters too!

Type of Weld: Not all welds are created equal—fillet, groove, or others.

Weld Size & Throat: Getting these dimensions right ensures durability.

We get it—these factors may seem technical, but they’re the building blocks of a strong and safe structure.

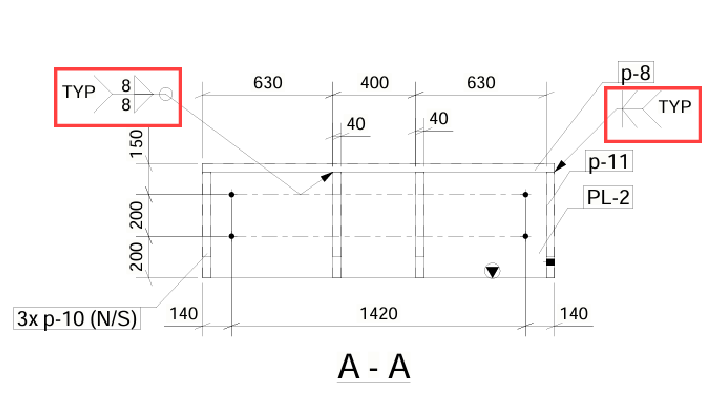

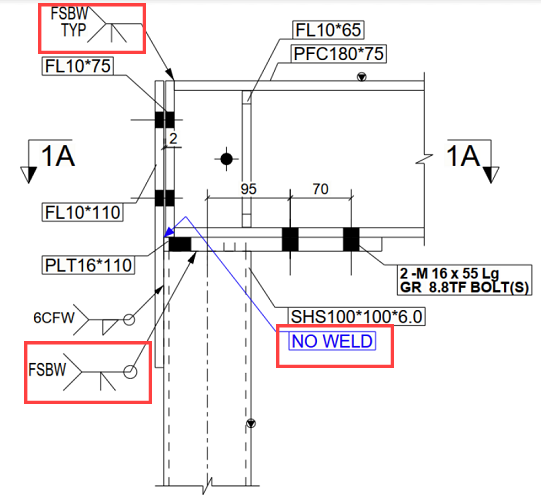

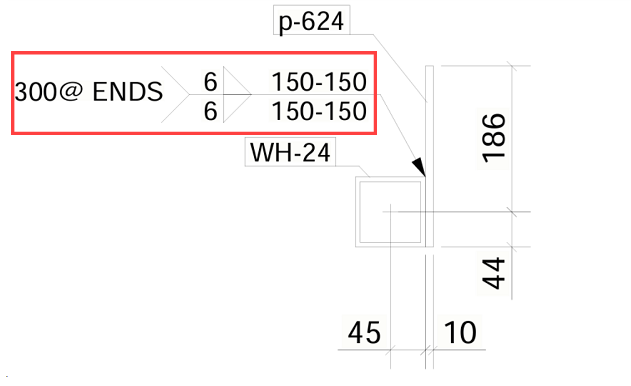

The Magic of Welding Symbols

Welding symbols are like a universal guide for your project. They make sure everyone—designers, engineers, and welders—is on the same page.

They save time.

They reduce errors.

They maintain quality.

At Sharcon, we believe welding symbols are the easiest way to bring clarity to your shop drawings. When your welder knows exactly what to do, you get consistent and accurate results—every time.

What Happens When a Weld is Missed?

Missing a weld might not seem like a big deal—until it is - Imagine this:

A missed weld makes it past the shop, into assembly, through the paint booth, and beyond.

Then, someone notices

Now, you’re reworking every step—wasting time, money, and materials.

We know how frustrating that can be, and that’s why we make sure every weld detail is clear and accounted for in our shop drawings.

How Sharcon Makes It Easy for You?

Here’s how we keep your projects on track and stress-free:

Clear Standards:

We follow the structural steel welding as per AS/NZS1554. All welds in our shop drawings default to 6CFW (Continuous Fillet Weld) unless the engineer specifies otherwise. You’ll always find this in our Shop Drawing General Notes for easy reference.

Special Welds? No Problem!

If the engineer has specific weld requirements, we include them in the drawings—no guesswork, no surprises.

Collaboration:

We take the time to understand which weld details are critical for your fabrication design, so there’s no room for error.

Why You Should Work with Sharcon?

We know what matters to you:

Clear, accurate drawings.

Minimal rework.

On-time, high-quality results.

By focusing on the details that matter most to fabricators and builders, we make your job easier and your projects more successful.

Let’s Build Together

Welding is the backbone of steel structures, and precision is key. At Sharcon, we’re here to support you with detailed shop drawings that save time, reduce costs, and ensure your projects are built to last.

Got questions about your next project? Let’s connect.

📞 Call us: +61 478 727 338

📧 Email us: shyam@sharcon.com.au

🌐 Visit our website: www.sharcon.com.au

Comments