The Versatile Flat Bar: Essential in Steel Detailing

- gokul raj

- Jan 3

- 2 min read

When talking about steel detailing, one of the unsung heroes in the industry is the humble steel flat bar. Despite its simplicity, the flat bar plays a crucial role in various construction and fabrication projects. Let’s dive deeper into what makes this material so indispensable.

What is a Steel Flat Bar?

Imagine a flat, rectangular piece of solid steel with square edges—that’s a flat bar. Its design might seem straightforward, but its versatility and strength make it a favorite across industries, including construction, fabrication, and transportation. Flat bars are commonly used for framework structures, transport trailers, and even smaller DIY projects. Their adaptability ensures they’re a go-to choice for many professionals.

Features and Benefits of Flat Bars

Why are flat bars so popular? Here are some standout features and benefits:

Variety of Sizes and Material Grades: Available in numerous options to suit different project needs.

Cost-Effective: Offers excellent value without compromising on quality.

Meets Industry Standards: Exceeds the minimum requirements of AS/NZS 3679.1.

Ease of Fabrication: Can be cut, drilled, and formed effortlessly.

Welding-Friendly: No pre-heating required.

Typical Uses of Flat Bars

Flat bars are widely appreciated for their performance and durability. Here’s where they shine:

Fabrication: Simplifies complex construction processes.

High Strength-to-Weight Ratio: Ensures robust support without excessive weight.

Storage and Transportation: Easy to handle and store due to their shape and size.

Durability: Built to last, reducing maintenance and replacement costs.

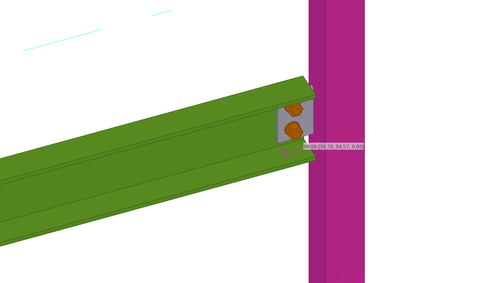

How We Use Flat Bars in Steel Detailing

At Sharcon, flat bars are an integral part of our detailing and fabrication process. Here’s why:

Minimizing Material Wastage: By carefully categorizing plates into flat bar dimensions, we optimize material use.

Streamlining Fabrication: Flat bars are easier to work with, speeding up the production process.

Precision Ordering: Using our PLATE LIST reports, fabricators can determine the exact flat bar sizes needed and order them directly, saving time and effort.

Why It Matters

For professionals in the steel detailing industry, understanding the value of flat bars can make a significant difference in project efficiency and cost savings. By leveraging their unique features and integrating them into the detailing process, we ensure high-quality outcomes that meet industry standards.

Let’s Discuss!

Have questions about using flat bars in your projects? Or want to explore how we can help optimize your steel detailing processes? Let’s connect and dive deeper into solutions tailored for your needs!

📞 Call us: +61 478 727 338

📧 Email us: shyam@sharcon.com.au

🌐 Visit our website: www.sharcon.com.au

Comments