Shear Studs: The Hidden Heroes of Composite Construction

- gokul raj

- Jan 3

- 2 min read

Updated: Jan 3

When we talk about the seamless integration of steel and concrete in construction, one unsung hero often takes center stage: shear studs. These small, heavy-duty connectors are the backbone of composite structures, ensuring strength, stability, and longevity. Let’s dive into what makes shear studs indispensable and how they work their magic in the steel detailing industry.

What Are Shear Studs?

Shear studs are more than just metal connectors; they are the key to unlocking the full potential of steel-concrete composite construction. Welded onto steel beams or decking, these connectors ensure that steel and concrete act as one cohesive unit. Whether you call them weld studs or shear connectors, their purpose remains the same: enhancing the structural integrity of modern construction projects.

Have you ever wondered why composite structures are so much stronger than traditional materials? Let’s explore how shear studs make this possible.

How Do Shear Studs Work?

The role of shear studs is as fascinating as it is crucial. Here’s a closer look at their functionality:

Bonding Steel and Concrete: Think of shear studs as the bridge between two worlds. Steel excels in tension, while concrete shines in compression. Shear studs create a mechanical bond that allows these materials to complement each other seamlessly.

Shear Transfer: Picture a structure facing the forces of heavy traffic or strong winds. These forces generate shear stress at the interface of steel and concrete. Shear studs transfer these forces effectively, ensuring the materials stay connected and work in unison.

Enhanced Structural Performance: By facilitating the collaboration of steel and concrete, shear studs significantly boost the load-bearing capacity of structures. This feature is vital for high-rise buildings, bridges, and other large-scale projects.

Next time you walk on a bridge or enter a high-rise, think about the invisible connectors making it all possible. It’s a subtle yet profound contribution to our built environment.

Applications of Shear Studs in Construction

Shear studs are everywhere once you start looking! Here are some of their key applications:

Bridge Construction: They create composite bridge decks that withstand heavy traffic loads with ease.

High-Rise Buildings: Essential for distributing loads efficiently, shear studs enhance the structural performance of tall buildings.

Parking Structures: They ensure parking floors can handle dynamic and static loads without breaking a sweat.

Industrial Floors: Factories and warehouses rely on shear studs for robust floors that endure heavy machinery and operational stresses.

Our Approach at Sharcon

At Sharcon , we take pride in making the complex simple. Our expertise in shear stud detailing ensures that your projects run smoothly and efficiently. Here’s how we do it:

Detailed 3D Modeling: Precision is key, and our 3D models ensure shear studs are perfectly aligned with design specifications.

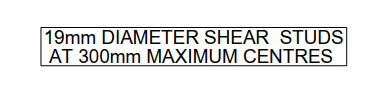

Accurate Placement and Spacing: Proper spacing is non-negotiable. We guarantee compliance with engineering designs, enhancing structural performance.

Welding and Fixing Details: Our shop drawings provide clear, actionable instructions for on-site implementation, minimizing errors and delays.

Let’s Talk!

Shear studs may be small, but their impact is enormous. At Sharcon, we’re here to ensure they’re detailed, modeled, and implemented to perfection. Got questions or a project in mind? Reach out to us, and let’s create something exceptional together.

📞 Call us: +61 478 727 338

📧 Email us: shyam@sharcon.com.au

🌐 Visit our website: www.sharcon.com.au

Comments