ChemSet vs TruBolts in Steel Structures

- gokul raj

- Jun 7, 2025

- 2 min read

When anchoring steel structures to concrete, selecting the right anchoring system is crucial for long-term structural stability, load-bearing performance, and compliance with design requirements. Two widely used anchoring methods in structural steel applications are ChemSet (chemical anchors) and TruBolts (mechanical expansion anchors).

Although both are proven solutions, they differ significantly in terms of installation process, performance characteristics, and suitable applications. Below is a structured comparison to assist you in selecting the most appropriate anchor type for your project.

1. ChemSet Anchors (Chemical Anchoring Systems)

ChemSet refers to a chemical anchoring technique in which a two-part resin (epoxy, vinylester, or polyester) is used to bond a threaded rod or rebar into a pre-drilled concrete hole. The chemical compound hardens and adheres to both the concrete and the embedded steel element, forming a high-strength bond.

Key Characteristics

High load-bearing capacity, even in cracked concrete

Suitable for close-to-edge and shallow embedment conditions

Excellent resistance to vibration, dynamic loads, and seismic activity

Requires curing time before load application

Demands strict hole preparation (cleaning and drying) for optimal performance

Common Use Cases

Retrofit installations

Overhead or wall-mounted steel structures

Applications with limited edge spacing or shallow concrete members

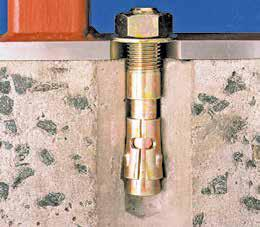

2. TruBolts (Mechanical Expansion Anchors)

TruBolts are mechanical anchors that rely on expansion force. A bolt is inserted into a drilled hole, and as it is tightened, a sleeve expands outward, pressing against the walls of the concrete to form a secure hold.

Key Characteristics

Immediate load-bearing capacity post-installation

Straightforward and quick installation

Performance depends on concrete condition (best suited for uncracked concrete)

Requires sufficient embedment depth and edge distance to prevent breakout

Common Use Cases

Temporary or fast-track installations

General-purpose steel-to-concrete fixings

Areas where curing time is not feasible due to tight schedules

Comparison Summary

Feature | ChemSet Anchors | TruBolts Anchors |

Anchor Type | Chemical Bond | Mechanical Expansion |

Load Performance | Superior in cracked/dynamic conditions | Moderate, suitable for static loads |

Installation Time | Requires curing | Immediate load application |

Hole Cleaning Requirement | High | Moderate |

Best For | Retrofit, seismic zones, edge conditions | Fast-track, non-critical fixings |

Concrete Condition Suitability | Cracked or uncracked | Uncracked (ideal) |

Recommendation

For high-performance structural applications, especially in retrofit projects, seismic zones, or where concrete edge distances are limited, ChemSet anchors are the preferred solution.

For standard applications where speed and ease of installation are key and the concrete is in good condition, TruBolts offer a practical and cost-effective choice.

Please feel free to share the specific conditions of your site or structural elements, and we’ll be happy to advise on the most suitable anchoring system tailored to your project requirements.

📞 Call us: +61 478 727 338

📧 Email us: shyam@sharcon.com.au

🌐 Visit our website: www.sharcon.com.au

Comments