Reduced Level (RL): Core of Steel Detailing

- gokul raj

- Dec 26, 2024

- 2 min read

Updated: Dec 27, 2024

Let’s talk about Reduced Level (RL)! In steel detailing, RL is an indispensable reference point. It determines the vertical distance between a specific survey point and a designated datum plane, ensuring every component of a steel structure aligns perfectly. Precision in RL is what brings steel structures to life with accuracy and efficiency. Let’s explore its relevance and application in steel detailing.

Key Types of Levels in Steel Detailing

Here are some levels specific to steel detailing and their importance:

FFL (Floor Finished Level): The final height of the floor after finishes, crucial for aligning steel components with architectural elements.

SSL (Structural Slab Level): The reference point for placing steel reinforcements and connections within slabs.

FCL (Finished Ceiling Level): Guides the placement of steel bracing and ceiling attachments, ensuring consistency with design requirements.

SFL (Structural Floor Level): Forms the base reference for vertical steel elements like columns and walls.

Why RL Matters in Steel Detailing: A Practical Perspective

FFL (Floor Finished Level)

Alignment with Architectural Plans: Ensures that steel elements such as beams and columns integrate seamlessly with finished floors.

Drainage and Accessibility: Helps maintain proper elevations for structures like ramps and platforms.

SSL (Structural Slab Level)

Provides a clear reference for embedding steel reinforcements or connections, ensuring slab integrity and alignment.

FCL (Finished Ceiling Level)

Facilitates the precise installation of steel hangers and bracings for ceiling systems, lighting fixtures, and HVAC components.

SFL (Structural Floor Level)

Ensures accurate placement of base plates and vertical steel components, avoiding misalignments that could compromise the structure.

How Sharcon Incorporates RL in Steel Detailing

At Sharcon, we go beyond just annotations; we ensure RL is a guiding factor in every detail of steel construction. Here’s how:

B.O.B.P (Bottom of Base Plate)

The starting point for stability. Precise placement guarantees even load distribution and secures the connection between steel columns and foundations.

B.O.S (Bottom of Steel)

Ensures all structural steel aligns with design specifications, preventing misalignment or uneven loads.

T.O.S (Top of Steel)

Critical for accurate alignment of beams and trusses, enabling seamless connections between structural members.

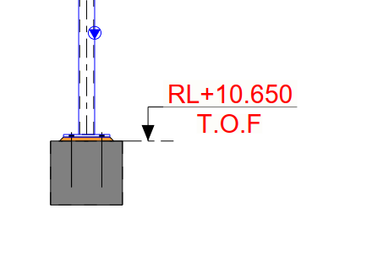

T.O.Slab & T.O.Footing

These references ensure that steel embeds and connections align perfectly with slabs and foundations, preventing structural discrepancies and enhancing load distribution.

Why Choose Sharcon for Steel Detailing?

We understand that precision in RL is non-negotiable in steel detailing. By incorporating detailed RL annotations in our layouts, we:

Simplify the review process.

Ensure on-site execution is error-free.

Maintain compliance with structural and architectural specifications.

Whether you need assistance with RL planning, annotation, or its integration into steel detailing workflows, Sharcon has the expertise to deliver. Let’s collaborate to ensure your steel structures stand tall, strong, and precise.

Got questions about your next project? Let’s connect.

📞 Call us: +61 478 727 338

📧 Email us: shyam@sharcon.com.au

🌐 Visit our website: www.sharcon.com.au