Chamfer: Enhancing Steel Detailing for Durability and Precision

- gokul raj

- Jan 30, 2025

- 2 min read

Chamfering plays a crucial role in steel detailing, ensuring precision, safety, and longevity in structural components. Whether for fabrication, assembly, or galvanizing, chamfered edges improve both functionality and aesthetics. Let’s explore how chamfers contribute to superior steel detailing and why they matter in construction.

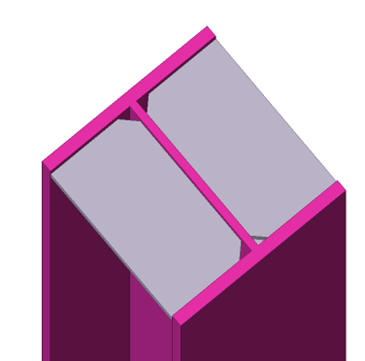

What is a Chamfer?

A chamfer is a beveled edge cut at a specific angle, typically 45 degrees, across adjoining right angles. These beveled edges provide clearance for mating parts, simplify assembly, and eliminate sharp edges to enhance safety. Chamfers are commonly applied to brackets, enclosures, faceplates, and various structural steel components.

Types of Chamfers

Straight Chamfer – A uniform bevel along the edge for a smooth finish.

Partial Chamfer – A chamfer applied only to a section of the edge.

Mitered Chamfer – A chamfered edge at a miter joint, ensuring seamless connections.

Radial Chamfer – A rounded chamfer for smoother transitions between surfaces.

Applications of Chamfering in Steel Detailing

Optimizing Surface Preparation for Galvanizing

Chamfering steel edges before galvanizing ensures an even zinc coating, preventing poor adhesion and weak points. Sharp edges can cause uneven coating, while chamfers facilitate better zinc distribution, enhancing corrosion resistance and durability.

Reducing Stress Concentrations

Steel undergoes thermal expansion during galvanizing, and sharp edges can create stress points leading to warping or material distortion. Chamfering helps distribute heat evenly, minimizing these risks and ensuring structural integrity.

Preventing Excess Zinc Buildup

When steel is dipped into molten zinc, sharp edges can cause excessive zinc accumulation, resulting in an uneven finish. Chamfered edges allow for smoother drainage, preventing unnecessary buildup and ensuring a uniform, professional appearance.

Enhancing Safety and Handling

Chamfered edges reduce the risk of cuts and injuries during fabrication and transport. Smooth edges improve worker safety, making steel components easier to handle and assemble without compromising structural strength.

Preventing Cracking and Corrosion

Sharp corners can become stress concentration points, leading to cracks or corrosion over time. Chamfering alleviates these weak spots, extending the lifespan of steel components, particularly in outdoor or industrial applications.

Meeting Industry Standards

Many structural codes and quality assurance standards require chamfered edges for precision and safety. By integrating chamfers, steel components meet compliance requirements while maintaining aesthetic and functional excellence.

Why Clients Choose 'Sharcon' for Chamfering Excellence

At Sharcon, we tailor chamfering solutions to meet project-specific needs, ensuring precise detailing for fabrication, assembly, and finishing processes.

Precision Chamfering: We provide whole-number chamfer values such as 10mm, 15mm, and 20mm, aligning with steel profile rounding radius requirements.

Galvanized Steel Optimization: For hot-dip galvanized steel, we apply higher chamfer values, allowing smooth zinc drainage and preventing coating defects.

Comprehensive Fabrication Support: Alongside chamfering, we incorporate vent holes for better galvanization efficiency, ensuring quality and longevity.

Structural Integrity and Efficiency: Our detailing minimizes shop and site work, improving overall buildability and cost-effectiveness.

Chamfers may be a small detail, but they make a significant impact on steel detailing and fabrication. At Sharcon, we ensure every component is engineered for strength, precision, and durability. Partner with us for expert detailing solutions that enhance efficiency and performance in every project.

📞 Call us: +61 478 727 338

📧 Email us: shyam@sharcon.com.au

🌐 Visit our website: www.sharcon.com.au